To create a watch takes a tremendous number of machines and expertise. Please enjoy seeing and learning about the special machines that we use to create our watches. Please feel free to reach out with any questions. We love educating about what we do and have amassed some of the nicest machines in the industry.

Workshop

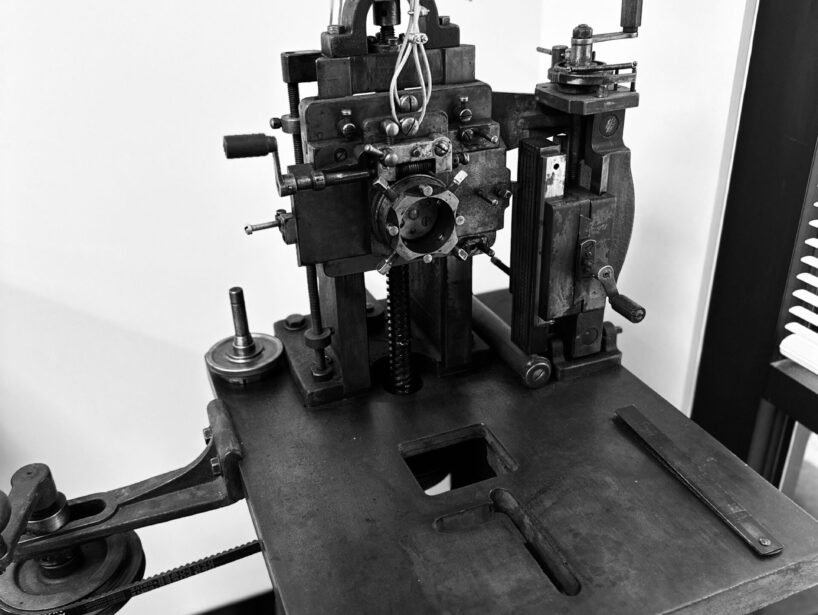

Engine-Turning Machines

These are the machines we use to make the intricate geometric patterns on our dials, cases and movements. Featured here are ;One Leinhard Straight line machine Circa 1915, Two G.Plant Rose Engine machines Circa 1925, Three Neuweiler Engelsberger Straight line Machines Circa 1950, Lindow Rose Engine Machine Circa 2018.

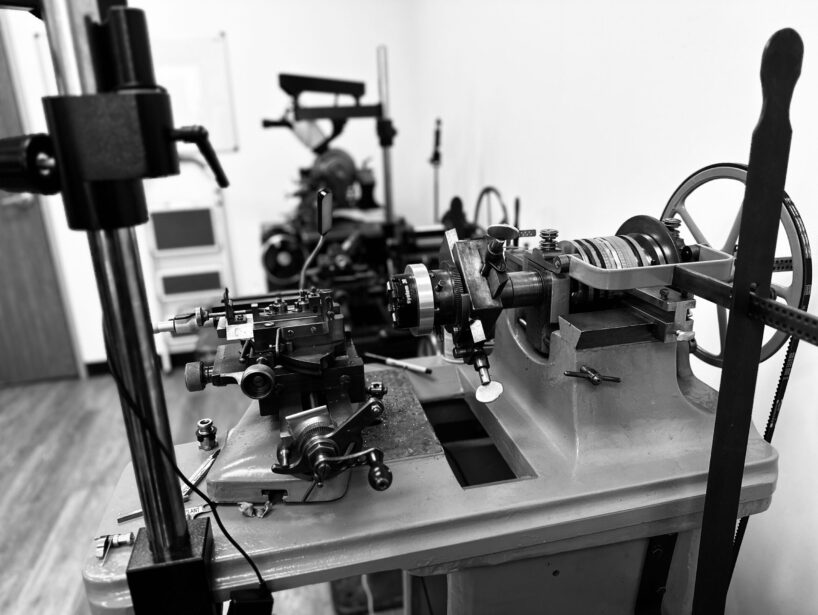

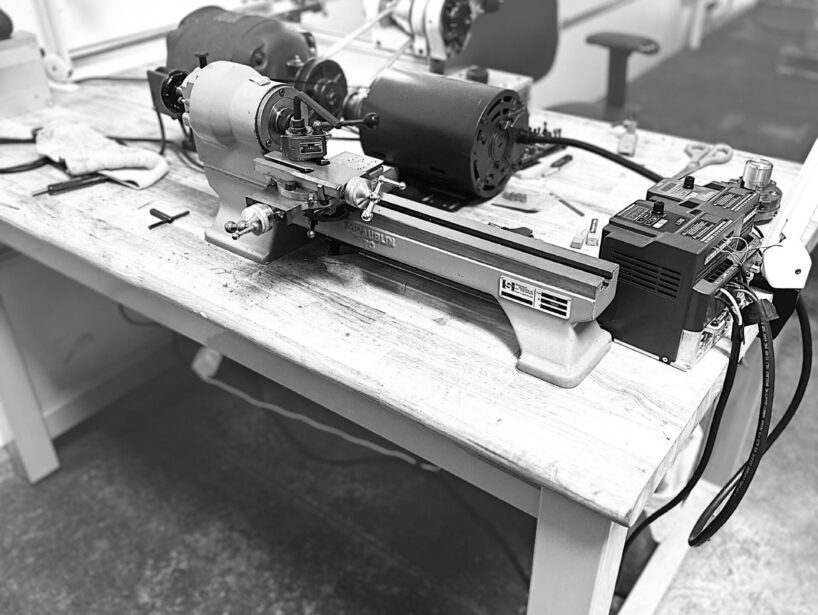

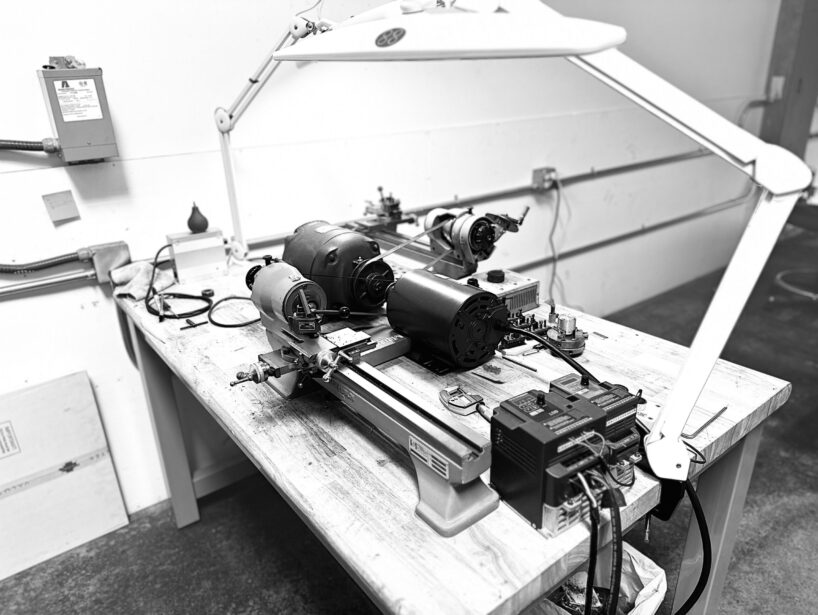

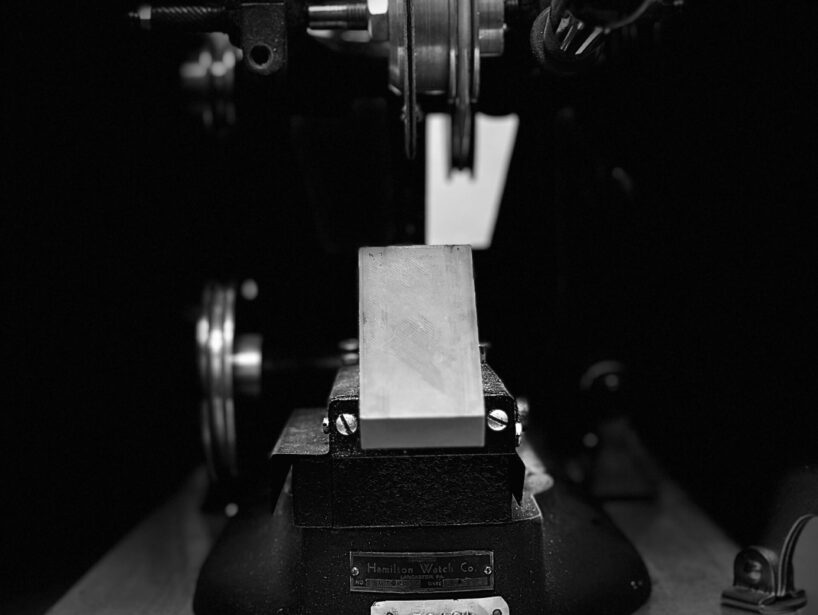

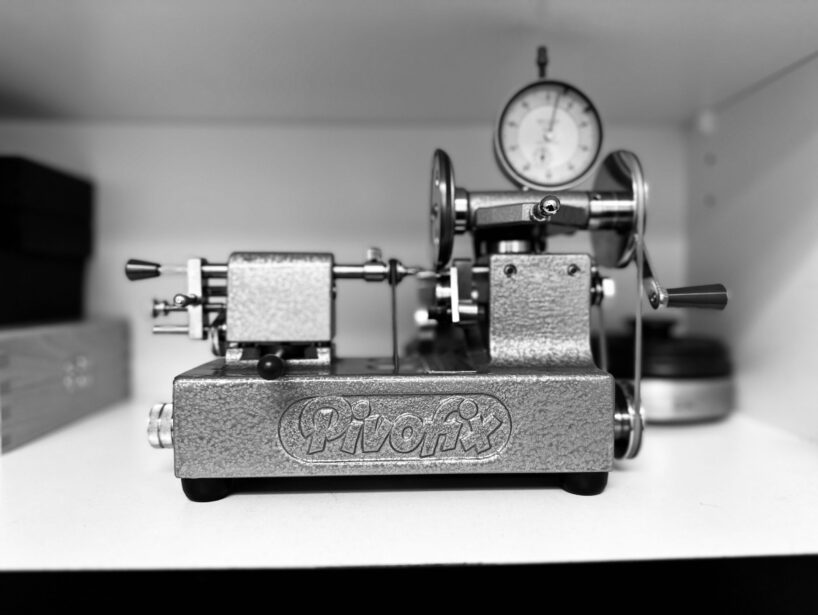

Manual Machinery

Manual machines are used to produce parts one at a time without any computer assistance. We use them to manufacture or modify many of the parts in our watches. For instance a single pinion for a watch is created on three different machines. Featured here are; Two Schaublin 70 Lathes, Hauser Pinion Polisher, Levin 10mm Lathe, Schaublin 102 Lathe, Boley F1 Lathe, Pivofix for polishing pivots,various collets and accessories, Hardinge HLV-H Lathe.

Automatic Machinery

If only using manual machinery it would take one year to make one watch. Therefore, in order to meet demand ( and have a viable business) we use Automatic machinery to help create labor intensive watch components. This allows us to focus on the parts and finishes we prefer to do manually or by hand. The machines featured here are: Foba 50 Watt Fiber Laser , Brown & Sharpe Computer measuring machine, Kern Evo ( The first in the US for watchmaking and capable of sub-micron precision), Two Haas Office Mills, Schaublin 102TM , Citizen L12.